What are the benifits of microporous materials for coveralls?

Jul 10, 2023

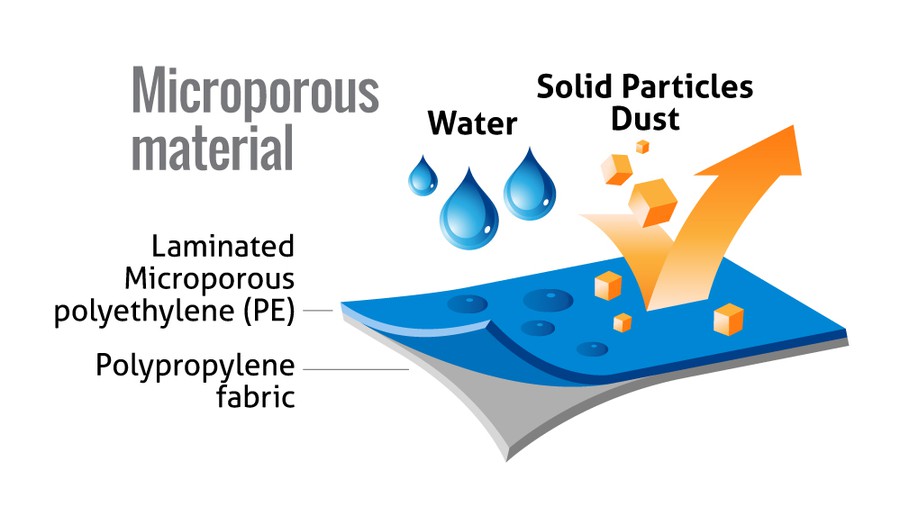

Microporous materials have become increasingly popular in the production of coveralls for a variety of industries due to their many benefits. These materials are specially designed to provide superior protection against hazardous substances while maintaining breathability and comfort for the wearer. Below are some of the benefits of using microporous materials for coveralls.

1. Protection against hazardous substances

Microporous materials provide excellent protection against hazardous substances. These materials are designed to be impermeable to many types of substances, including chemicals, oils, and blood-borne pathogens. This makes them an ideal choice for industries such as healthcare, chemical manufacturing, and industrial cleaning.

2. Breathability

One of the main advantages of using microporous materials for coveralls is their breathability. These materials are designed to be permeable to air and water vapor, allowing the wearer to stay cool and comfortable in hot and humid environments. This is especially important for industries that require workers to wear protective clothing for long periods of time.

3. Comfort

In addition to their breathability, microporous materials are also very comfortable to wear. These materials are lightweight and flexible, allowing for ease of movement and reducing fatigue. Microporous materials also have a soft, fabric-like feel, which makes them more comfortable to wear than traditional protective materials such as rubber or plastic.

4. Durability

Microporous materials are very durable and can withstand a lot of wear and tear. Unlike traditional protective materials such as rubber or plastic, microporous materials do not crack or tear easily, which means they can be reused multiple times. This makes them a cost-effective option for industries that require protective clothing.

5. Easy to clean

Microporous materials are also very easy to clean. They can be wiped down with a damp cloth or washed in a washing machine without losing their protective properties. This makes them a convenient and practical option for industries that require workers to wear protective clothing on a daily basis.

6. Versatility

Another advantage of using microporous materials for coveralls is their versatility. These materials can be used in a variety of industries, including healthcare, chemical manufacturing, and industrial cleaning. Microporous materials can also be used in a variety of applications, such as microporous coveralls, gloves, boot covers, and aprons.

7. Cost-effective

Microporous materials are a cost-effective option for protective clothing. They are cheaper than traditional protective materials such as rubber or plastic and can be reused multiple times. This makes them a practical and economical option for industries that require workers to wear protective clothing.

8. Environmentally friendly

Finally, microporous materials are environmentally friendly. The production of these materials does not require the use of harmful chemicals, and they can be recycled at the end of their lifespan. This makes them a sustainable option for protective clothing.

In conclusion, microporous materials offer many advantages for the production of coveralls and other protective clothing. They provide superior protection against hazardous substances while maintaining breathability, comfort, and durability. They are also cost-effective, versatile, and environmentally friendly. With these benefits, it is no wonder that more and more industries are choosing to use microporous materials for their protective clothing needs.