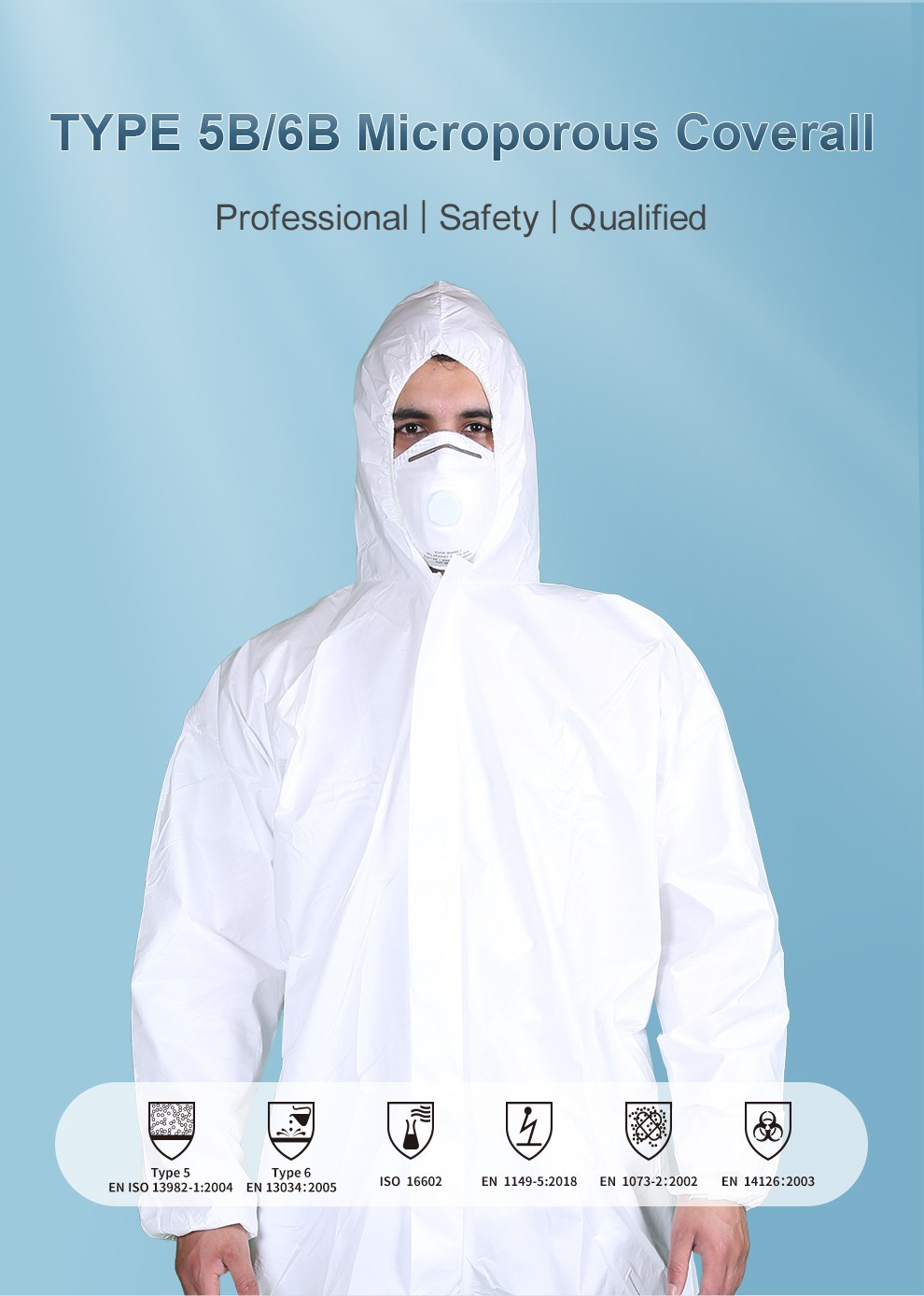

Microporous Coverall

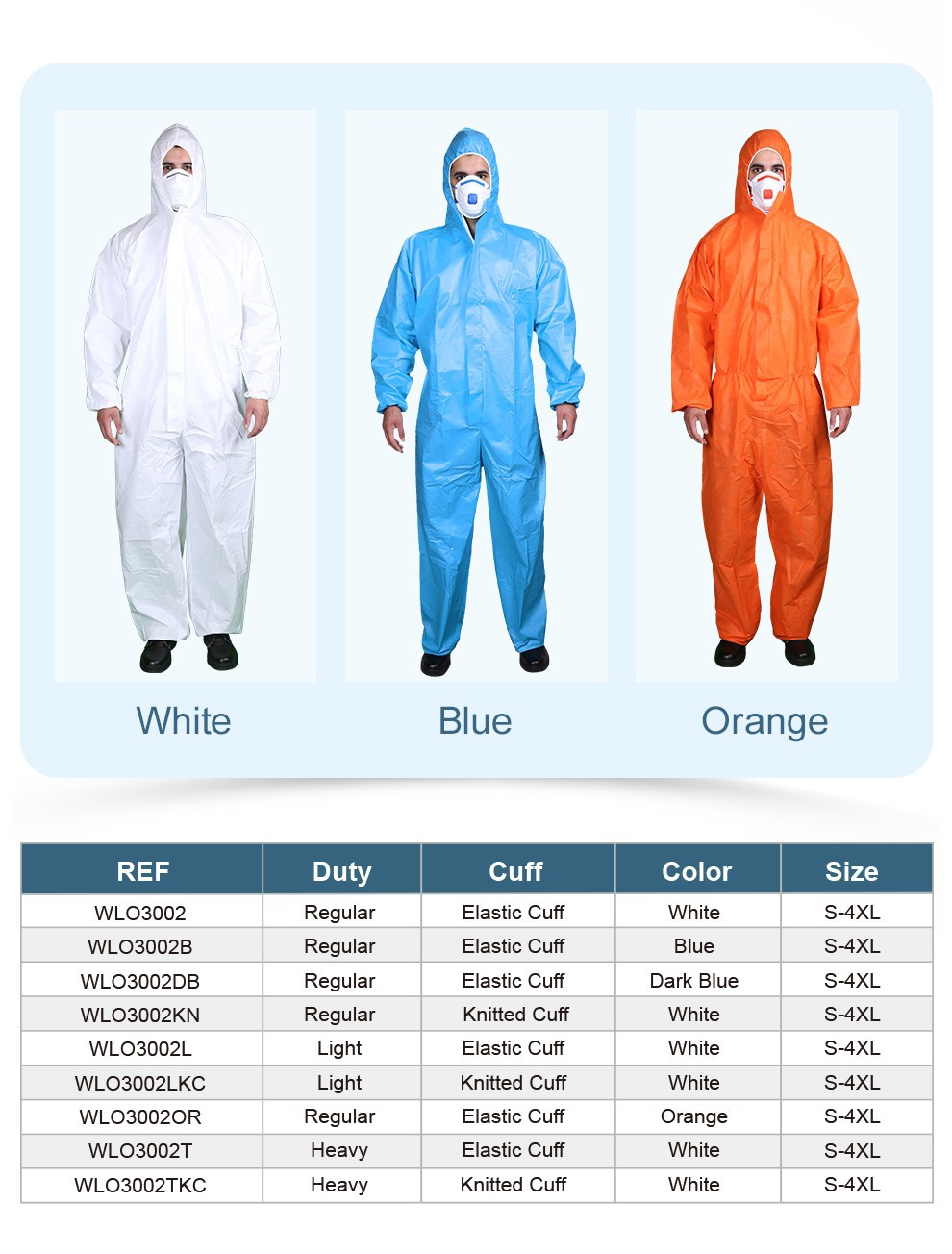

Article No.: WLO3002 & WLO3002T & WLO3002L & WLO3002KC

The microporous coverall is designed to provide full body protection for multiple applications including automotive refinishing, waste management, remediation, and more.

Seams with high protection of particulates and low level of liquid sprays or splashes.

Product Description

The microporous coverall is a high-quality protective garment suitable for any hazardous work environment that requires full-body protection. This coverall is made from a microporous fabric that effectively prevents liquid and particulate matter penetration without causing discomfort to the wearer.

In summary, the microporous breathable coveralls is a high-quality protective garment that provides superior protection against liquid and particulate matter. It is lightweight, durable, and breathable, making it ideal for use in any hazardous work environment.

Product Specifications

| Brand | HEALEECARE |

| Model Number | WLO3002 |

| Material | Microporous film laminate |

| Size | S/M/L/2XL/3XL/4XL |

| Color | White/Blue/Dark Blue/Orange |

| Certification | CE, ISO 9001, ISO 13485, FDA, Sedex |

| PPE Category | Category III |

| Protection Standards | EN ISO 13982-1, EN 13034, EN 1073-2, EN 14126, EN 1149-5 |

| Performance Levels | Type 5B, Type 6B |

| Applications | Medical, Industrial, Chemical, Agricultural, Cleaning, Disinfection, Painting |

| Shelf Life | 3-5 Years |

| Package | 1 PC/Polybag, 25/50 PCS/Carton, Vacuum packing available |

Product Features

1. Breathable: The microporous fabric allows the wearer to maintain a comfortable temperature without causing overheating.

2. Lightweight: The coverall is made from lightweight materials that make it easy to wear and move around in.

3. Superior protection: The Type 5B/6B Microporous Coverall provides protection against liquid and particulate matter, making it ideal for use in cleanrooms, chemical plants, and other hazardous work environments.

4. Durable: The coverall is designed to withstand rough handling, making it long-lasting and cost-effective.

Product Applications

1. Chemical plants: The disposable microporous coverall provides protection against chemicals, making it suitable for workers in chemical plants.

2. Cleanrooms: The coverall is designed to protect workers from contamination in cleanrooms, making it ideal for use in pharmaceutical and electronics manufacturing.

3. Hazardous environments: The Type 5B/6B Microporous Coverall is suitable for use in any hazardous environment where full-body protection is required.

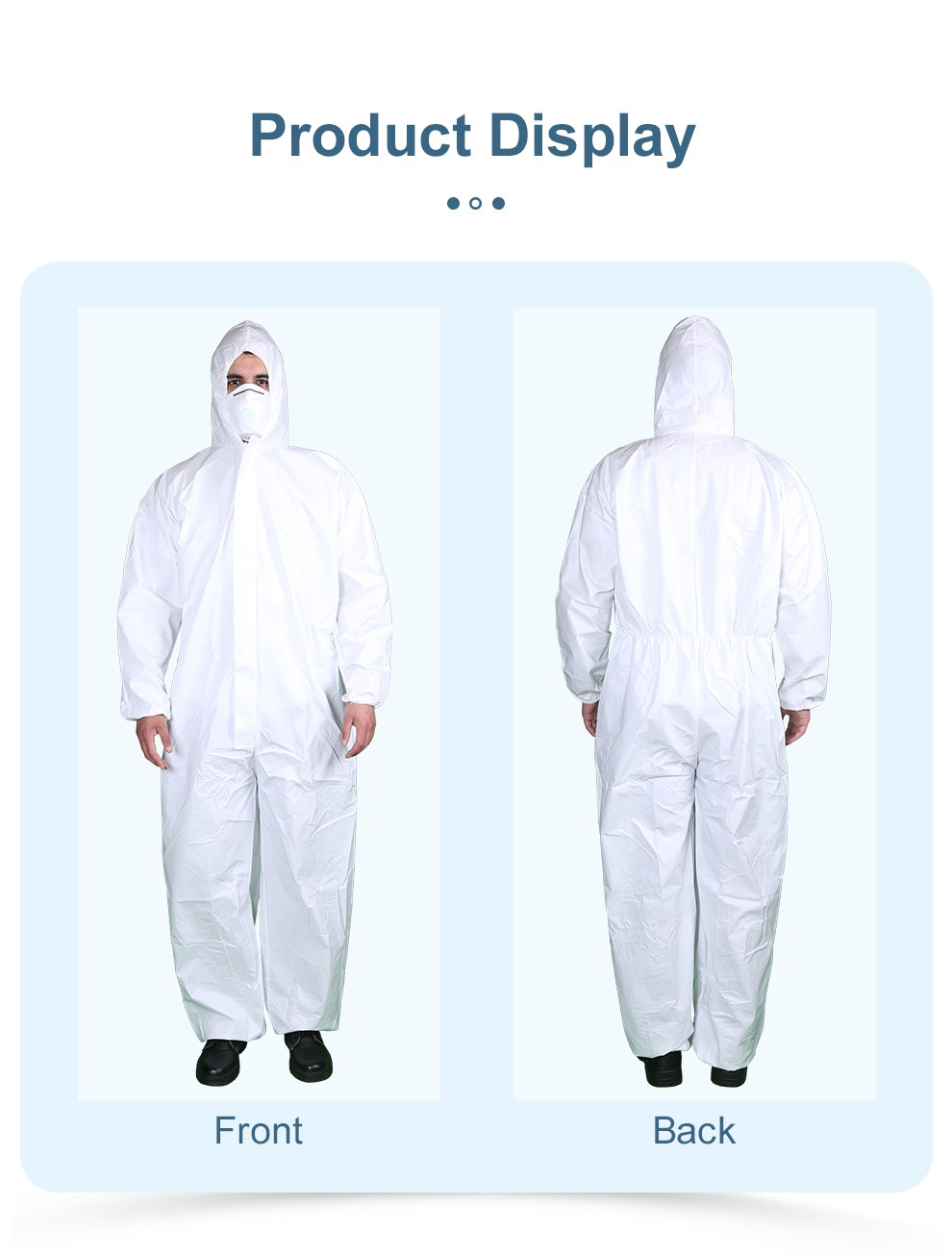

Product Pictures

Product Knowledge

The Standards

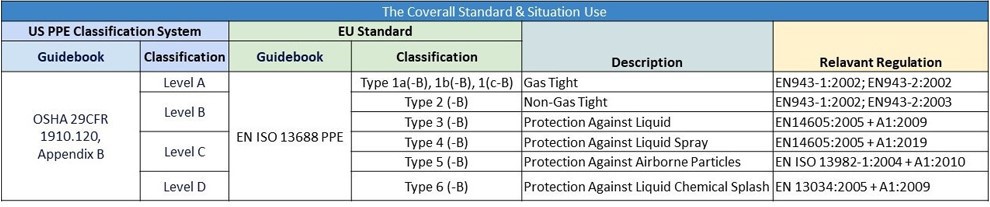

United States PPE Ratings

In the United States, there are no specific testing standards for coverall suit itself; however, there are 4 levels of situational standards that must be followed when using PPE.

Level A – required when you are working in the most hazardous environment and your skin, eyes, and respiratory need extra protection.

Level B – needed at the highest level of respiratory protection and skin protection need at a lesser level. It is included hazardous in waste sites, vapors, or gas.

Level C – needed when the concentration and airborne constituents are involved and need air-purifying respirators.

Level D – need minimum protection and hazards level of work is not included.

European PPE Ratings

EN ISO 13688 defines the requirements for a coverall. It specifies general performance requirements for ergonomics, innocuousness, size designation, aging, compatibility, and marking of protective clothing and the information to be supplied by the manufacturer with the protective clothing. The regulation further specifies the coveralls into 6 types of suits.

Type 1

Gas-proof suits: Fully sealed suits, EN 943.

Type 2

Limited gas-tightness. Suits prevent dust, liquids and vapours from penetrating at overpressure, EN 943.

Types 3 & 3B

Liquid-proof protection: Suits are approved to withstand compressed fluids e.g. from hoses and nozzles. The suits must have welded seams. Penetration testing has to be conducted according to EN 369 to provide information on protection in relation to individual chemicals, EN 14605. Type 3B protects against biologically contaminated particles, EN 14126.

Types 4 & 4B

Splash-proof protection: Suits are approved for the saturation of a liquid that can condense on the suit. The suits must have welded seams. Penetration testing has to be conducted according to EN 369 to provide information on protection in relation to individual chemicals, EN 14605. Type 4B protects against biologically contaminated particles, EN 14126.

Types 5 & 5B

Protect against harmful substances, EN 13982 Type 5B protects against biologically contaminated particles, EN 14126.

Types 6 & 6B

Limited splash-proof protection. Protect when there is a risk of splashing on the suit, EN 13034. Type 6B protects against biologically contaminated particles, EN 14126.

What is a Type 5/6 coverall?

Type 5 suits are full-body protective items covering the trunk, arms, and legs, such as one-piece coveralls or two-piece suits, which can be with or without hoods, visors, and foot covers. Type 5 is tested to verify its resistance to dust and particles.

Specifically, the test for Type 5 includes exposure to a dry aerosol with a particle size of 0.6um. The test result should indicate that the inward leakage of the aerosol must be below a minimum threshold.

Type 6 suits, offering the lowest level of protection, are designed to protect against splashes and light sprays.

Therefore, Type 6 protective suits are suitable for environments where occasional splashes by liquids of relatively low toxicity are possible (e.g., paints). Figure 3 to Figure 6 are the images of Type 3 to 6 protective suits.

Send Inquiry