Safety prevention measures for toxicosis of productive occupation

Feb 27, 2023

As productive toxicosis mainly come from the production environment of workers, therefore, measures should be taken to eliminate, control or minimize the damage of poisons to workers. Specific how to prevent occupational poisoning, can start from the following aspects:

Elimination and control the toxins in the production environment

1. Eradication of toxins: to eliminate toxic substances from the production process. Firstly replace toxic substances with non-toxic substances as far as possible, and replace highly toxic substances with low-toxic substances when it is impossible to do so, so as to limit the content of toxic substances in chemical raw materials, such as replacing mercury rectifier with silicon rectifier; Replacing mercury meters with non-mercury meters; Zinc barium white, titanium barium white instead of lead white paint.

2. Reduce the concentration of poisons: reduce the concentration of poisons in the production environment, reduce the level of human exposure to poisons, so as to ensure that no health hazards to workers is the key to prevent occupational poisoning. The main purpose is to reduce the concentration of poisons in the production environment to meet the requirements of national and industrial standards. Therefore, it is necessary to strictly control the chance of the poison escaping into the production environment to avoid direct touch with the operator; For the escaped poison, prevent its spread, and purify the back of the factory.

3. Process, construction layout: the layout of the production process should not only meet the needs of production, but also meet the requirements of health. Production areas should be separated from each other in order to avoid overlapping effects. On the premise of conforming to the process design, the toxicity, concentration and contact population should be considered, and the gradient distribution should be presented. The source of productive poison escape should be arranged on the leeward side. For toxic substances that are easy to accumulate or be adsorbed, such as mercury, or factory buildings that can fly with toxic dust, the surface of the structure of the building should meet the sanitary requirements to prevent the accumulation of dust poison and the secondary flight of dust poison.

Personal protection: Personal protection is an important auxiliary measure in the prevention of occupational poisoning

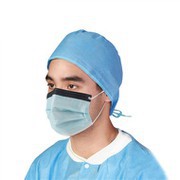

1. Rational use of personal protective equipment: Personal protective equipment includes protective hats, protective glasses, protective masks, protective clothing, air respirators, leather protective equipment, etc. The selection of personal protective equipment should pay attention to its protective characteristics and effectiveness. At the time of use, users shall be trained; Only by keeping good maintenance at ordinary times can it play its role well.

2. Do a good job of health monitoring: for the staff and workers who are exposed to toxic substances, occupational health examination should be carried out before and during the post, to eliminate occupational contraindications, find early health damage, so as to timely treatment.

3. Necessary sanitation facilities, such as lavatory equipment, shower room and changing room, should also be set up in places where toxic substances work. For poisons that can be absorbed through the skin or have great local effects, skin washing, disinfection and eye flushing facilities should also be equipped. For those exposed to toxic substances, reasonable provision of healthy food, appropriate physical exercise, enhance physical fitness, improve resistance.

Safety and health management measures

Unsound management system, equipment maintenance is not timely and illegal operation are often the main causes of occupational toxic. Therefore, it is important to take corresponding management measures to eliminate the risk factors that may cause occupational poisoning. Also, it is necessary to do a good job in the publicity and education of the occupational health knowledge of the enterprise management department and workers, improve their understanding and attention to the anti-virus work, and consciously implement the relevant occupational safety and health laws and regulations as well as the internal rules and regulations of the enterprise. Enterprises engaged in the highly toxic industry shall arrange professional personnel to regularly test the concentration of toxic substances in the air of the operating environment and control the concentration of toxic substances in the operating environment so as to make it conform to the national and industrial standards.