Current Situation And Prospect Of Personal Protective Equipment

Mar 23, 2023

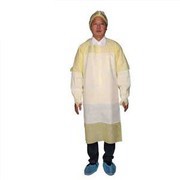

Personal protective equipment (PPE), known as labor protection articles in China, refers to personal wear articles used to protect employees from physical, chemical, biological and other harmful factors. It mainly includes head protection (safety hat), eye protection (eye protection), hearing protection (ear plugs), respiratory protection (protective mask), hand protection (gloves), foot protection (safety shoes), body protection (protective clothing), falling protection (safety belt), skin protection (hand sanitizer), etc.

At present, due to the COVID-19 epidemic, people's attention is focused on masks, protective clothing, protective gloves and other medical supplies, making the topic of personal protective equipment, which is not the focus of the original, hot. Countless manufacturers, distributors and certification bodies flocked to the industry, all hoping to make a fortune through masks and protective clothing. From the perspective of the industry association, more concern is the industry surplus after the epidemic "one place chicken feathers".

According to the information mastered by the association, briefly introduce the current industry status and future prospects:

I. Current situation

According to statistics, in 2019, the world's personal protective equipment market size was $55 billion, 70% of which was occupied by North America and Europe, but China and Southeast Asia accounted for 50% of the global production. In the Chinese market, 3M, Honeywell, Mesian, Delta, Ansell, Lakeland, Uvus and other international brands occupy the high-end market; Chinese manufacturers with brands such as Celit, Dunwang, Chomei, Gangkai, Xingyu and Nanhe as the backbone gradually catch up. A number of Chinese enterprises with OOO (such as Shanghai Dasheng) in product research and development, quality control, price positioning and other aspects have quite strong competitiveness. Especially in the industrial clusters of Gahigh-density in Shandong Province, Nantong in Jiangsu Province, Wenzhou in Zhejiang Province and Dongguan in Guangdong Province, protective masks, protective gloves, safety shoes, protective glasses, safety hats and other products are superior in style, function, quality and price.

On September 8, 2019, The State Council issued the decision on the adjustment of industrial product production license management catalog to strengthen the supervision in the event and after ", since April 7, 1984 began to include the production license management of special labor protection equipment to cancel evidence, which means that production enterprises production of 15 categories of special labor protection equipment will not need to apply for QS mark. The cancellation of the license system implemented for 35 years makes it clear that the supervision at the national level will shift from "before" to "after" in the future, and the self-discipline of the industry will become the mainstream, giving full play to the role of industry supervision and social supervision, and promoting the construction of a management system based on standards, enterprise compliance and government supervision. The quality and safety monitoring and early warning mechanism should be established through industry self-discipline to ensure the quality of products circulating in the market.

Further integration of domestic and foreign markets, capital began to enter China's personal protective equipment market. In May 2017, British Benze Group acquired Shanghai Hesaifu Security Technology Co., Ltd. and Shanghai Hean Protection Technology Co., Ltd. with a total price of 162 million yuan. Founded in 1854, the Benzse Group is a London-listed company and a member of the FTSE 100 Index. It now has $10 billion in sales worldwide, including $1.5 billion in sales of personal protective products. On June 18, 2019, Zhenkunhang Industrial Supermarket (Shanghai) Co., Ltd. announced the completion of a $160 million round of D financing led by Tencent, once again refreshing the largest single round of financing in China's MRO field so far. The customer demand of personal protective equipment, not only price competition, often more growth in the service. To industrial supplies one-stop procurement and service for the purpose of centralized, digital sales, whether can open up a new road for the development of the industry, is also the focus of the industry. The capital can enter into China's personal protective equipment market, especially into circulation enterprises, which shows that the development prospect of the Chinese market is optimistic.

Take protective masks for example: before the pandemic, China accounted for more than 50 percent of the world's production capacity. After the outbreak of the epidemic, 56 million masks were imported from abroad, basically buying up the world's face masks. Subsequently, various industries in China entered the game, more than 3,000 enterprises transformed into mask production, and the country rapidly increased production capacity, with the daily output already exceeding 100 million. China now produces 80 percent of the world's face masks.

For example, a foreign company purchased a pair of earplugs for hearing protection produced by a domestic company. The purchase price was RMB 10 yuan per pair, and the profit was already considerable. However, the final result was that the price of this pair of earplugs abroad was as high as RMB 160 yuan.

For example, a pair of mechanical gloves might sell for $50 in the high-end market in Europe or the United States, but may cost as little as $5 when manufactured domestically, a price difference of nearly 10 times. Because domestic OOO products into the European and American markets is not a single process, a considerable part of the local traders, even wholesalers several times to change hands, to the final customer price has increased several times. But it also means that Chinese personal protective equipment has a huge price advantage.

2. Risk

European and American markets have strict requirements for the entry of personal protective equipment made in China, and the products sold must meet local regulations and standards, which is the so-called "compliance". Personal protective equipment entering the EU requires mandatory CE certification, and entering the United States requires products to meet ANSI, FDA, NIOSH and other standards. Some willing enterprises are not familiar with product certification and do not understand it, so they dare not take this step. The main reason is that the exported products of these enterprises have been certified by the European Union, the United States, Australia and other countries and regions, so they are more familiar with the products entering these markets and have more advantages. Therefore, whether Chinese personal protective equipment manufacturers or trading enterprises, if they want to enter foreign markets, or do a good job of product certification, to avoid risks.

Take the most in-demand masks: in the past, EU CE certification took six months and was not cheap. FDA approval in the United States is more difficult, taking a year.

In response to the outbreak, the EU has introduced recommendations on compliance evaluation and market surveillance procedures for medical devices and personal protective equipment (PPE) during the outbreak. This recommendation does not mean no CE certification, but for protective masks during the pandemic, it suggests special access and market supervision requirements. But that does not mean giving up regulation. Masks will still have to be compliant when entering the EU.

The Centers for Disease Control and Prevention (CDC) has also released its Strategy for Optimizing the supply of N95 Masks: Crisis/Alternative Strategy, which states that while inconsistent with the requirements of the current medical standards system in the United States, during an expected or known shortage of N95 respirators, N95 respirators can be replaced by KN100, KP100, KN95, KP95 types conforming to Chinese standard GB2626 and FFP3, FFP2 conforming to European standard EN149.

With the large-scale outbreak of the epidemic in Europe and the gradual stability of the domestic epidemic prevention and control, a large number of domestic mask manufacturers want to export their products to Europe. The European Union classifies protective masks as FFP1, FFP2 and FFP3. Protective masks are covered by the (EU) 2016/425 Personal Protective Equipment Regulation, which is a Category III product. The test standard is EN149:2001 A1:2009. According to PPE Regulation (EU) 2016/425, protective masks must be certified in Module B (Type test certification) Module C2 (random supervision of internal quality control products) or Module D (Production process quality control) before they can be legally sold in the EU.

In short, it must be either Module B, Module C2 or Module B, Module D.

Only certifying notified bodies authorised by the European Commission (EU) 2016/425 PPE Regulation for Mask products Module B, Module C2 and/or Module D are entitled to undertake CE certification activities for protective masks.

Any certifying notified body that is not authorized by PPE regulation, does not have Module B, C2 and/or D qualifications, or is not a certifying notified body has no authority to conduct CE certification activities for protective masks.

At present, the most prominent problem exposed in China is that a large number of unqualified certification bodies and intermediary agencies, taking advantage of enterprises' ignorance of EU regulations, mislead enterprises to make wrong choices and issue a large number of invalid CE certificates, which makes enterprises face huge commercial and legal risks in the process of exporting to the EU.

3. Outlook

In China, personal protective equipment is an industry undergoing innovation and development. It will grow with the development of China's economy and tap its potential with the development of the international market. In the context of China's economic transformation and development and supply-side reform, China's personal protective products are also facing adjustment and development, as well as challenges and opportunities.

- With the gradual improvement of laws and regulations, the rigid consumption of protective products brought by the enhancement of personal safety awareness, and the rising price brought by product functional reform, China's personal protective products industry will usher in a new stage of development, which will gradually break the high-end market share of international brands in the Chinese market.

- There will be a number of group enterprises with capital strength, marketing ability and complete production or operation varieties that can compete with foreign brands in China's personal protective equipment industry, and there will be more industrial clusters of Chinese personal protective equipment. The existing industrial clusters will be led by leading enterprises, according to product classification, raw materials division of a new industrial cluster model.

- Group standards and enterprise standards will take the leading direction in China's personal protective equipment industry. On November 4, 2017, the 30th meeting of the Standing Committee of the 12th National People's Congress adopted the newly revised Standardization Law of the People's Republic of China. The new standardization law clarifies the legal status of group standards. This will further encourage industry associations to organize enterprises to develop group standards for protection higher than the national mandatory standards, so as to better improve product quality.

- E-commerce network platform will further expand the marketing market of Chinese PPE enterprises. With the development of e-commerce, many Chinese personal protective equipment enterprises have carried out marketing through various e-commerce platforms, or cross-border e-commerce as a new export trade mode, which will be conducive to the export of Chinese small and medium-sized personal protective equipment enterprises.

- Adhere to green, low carbon, environmental protection. Chinese personal protective equipment enterprises should not only do a good job of protecting people, but also do a good job of energy conservation and emission reduction in the production environment. With the rapid development of artificial intelligence and industrial automation, more and more factories begin to replace people with machines and replace labor force with a large number of equipment. For the industry, ramping up equipment means fewer workers are equipped with personal protective equipment. But at the same time, with the improvement of national laws and regulations, some kinds of work that cannot be replaced by equipment, along with the appreciation of labor force, enterprises will develop towards high-end and fashionable trend in the equipment of personal protective equipment, and the standard of per capita equipment will also be improved. Therefore, the industry will face both challenges and opportunities.

- Adhere to the path of innovative development and give full play to the Chinese craftsman spirit. Most of China's personal protective equipment enterprises are more imitation, less innovation, more production, less high-end. With the emergence of new materials and technologies, more and more enterprises will insist on product innovation, increase investment in science and technology, and cooperate with relevant scientific research institutions and colleges and universities to develop more personal protective equipment products made in China, so as to serve the safety of production.

Personal protective equipment (PPE) is a small industry, but it concerns people's lives, health and safety, and has attracted worldwide attention during the COVID-19 pandemic. It is hoped that Chinese personal protective equipment enterprises can lay a good foundation for Chinese national brands to go abroad through continuous self-improvement, and finally realize the goal of "made in China".