What is the standard of type 3 4 coverall?

Oct 20, 2023

In recent times, the world has witnessed a series of devastating diseases and other biological threats such as the COVID-19 pandemic, the Ebola virus and numerous other afflictions. These events highlight the importance of ensuring frontline workers have the correct Personal Protective Equipment (PPE). Among the various types of PPE, the Type 3 4 coverall stands out as one of the most effective tools in preventing contamination.

Type 3 4 coverall is designed to provide full body protection to individuals working in high-risk environments such as chemical contamination, infectious disease wards, medical labs, and other healthcare settings. It is specifically designed to offer protection against liquid aerosols, sprayed liquids and harmful dust particles. It is made up of a lightweight and breathable material that is designed to enable the wearer to work comfortably for extended periods.

So what exactly is the standard for a type 3 4 coverall? It is essential to understand that the standards for this type of PPE are set and reviewed by various regulatory authorities in different regions of the world such as the European Union and the United States. These regulatory authorities and agencies aim to ensure that their standards are enforced and followed by manufacturers and distributors of PPE across the globe.

Type 3 and 4 coveralls are typically tested and classified according to their resistance to liquid penetration and their ability to reduce the impact of hazardous elements. In the United States, for instance, the National Institute for Occupational Safety and Health (NIOSH) has set standards covering the construction quality of Type 3 4 coveralls, including the minimum requirements for materials, design configurations, and performance attributes.

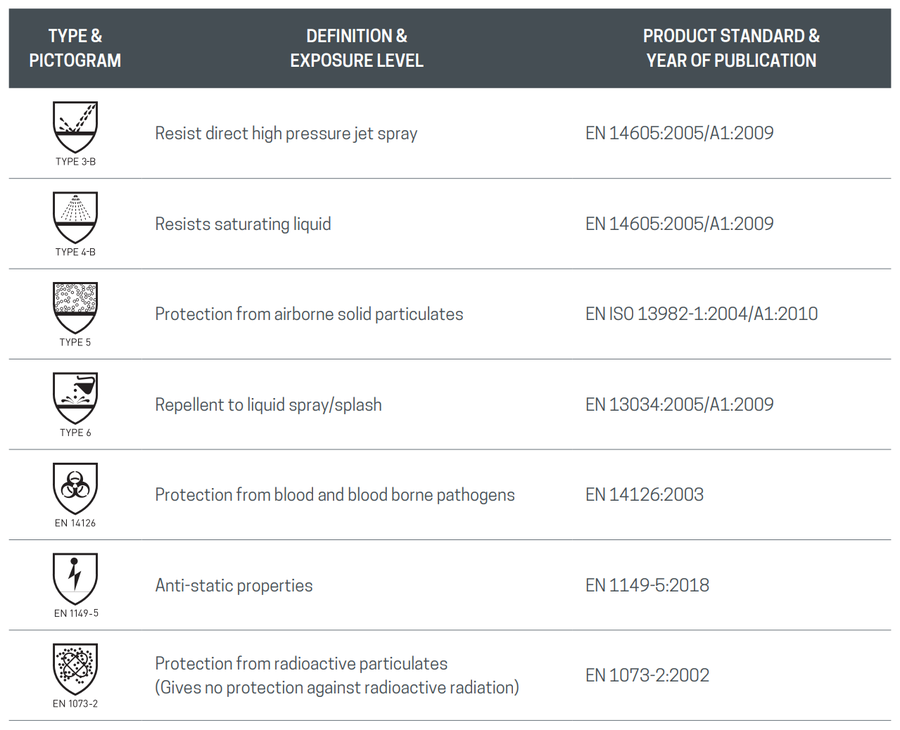

European standards, the EN14605 & EN13982-1/2 (type 3 and 4 respectively) also stipulate that coveralls must offer a barrier to penetration by liquid chemicals. The coveralls must pass specific tests and meet a pre-determined resistance level to qualify under the Type 3 and 4 categories. The European standard is very comprehensive, outlining specific tests such as the spray test, which is utilized to ascertain the penetration resistance of the material and seams when exposed to liquid chemicals.

In China, the National Standard for PPE AS 4565 - 2021 regulates the usage of type 3 4 Coveralls. The standard specifies the requirements, testing methods, as well as regulations regarding materials, construction quality, design, and performance for coveralls.

It is important to note that the standards are not uniform across regions, and companies that manufacture PPE are guided by the regulations in their respective countries. Also, customers may want to ensure that the product that they are considering for purchasing has undergone rigorous testing and certification. The correct PPE can be lifesaving and preserving the integrity of the product is paramount.

Going back to the garment itself, how do we know if it is the correct Type 3 4 coverall? The ANSI/ISEA 103-2010 sets out a specification capable of providing a minimum level of assurance that a specific garment conforms to the regulations. Manufacturers that have their PPE tested according to this specification can print a picture of a handshake on the neck or chest label to indicate the certification.

Type 3 4 coverall is a highly essential PPE garment to protect various employees from biological hazards and toxic chemicals. These coveralls protect workers from an array of health risks that could result in severe or possibly fatal injuries. Therefore, it is important to ensure that the garments you use adhere to locally or globally regulatory standards. As these standards can differ from region to region, it is essential to research the specific regulations that must be met in your region. By ensuring that your workers wear the correct PPE, you are taking a responsible and proactive step toward protecting your workers' safety and well-being.