What are coveralls made out of?

Dec 14, 2021

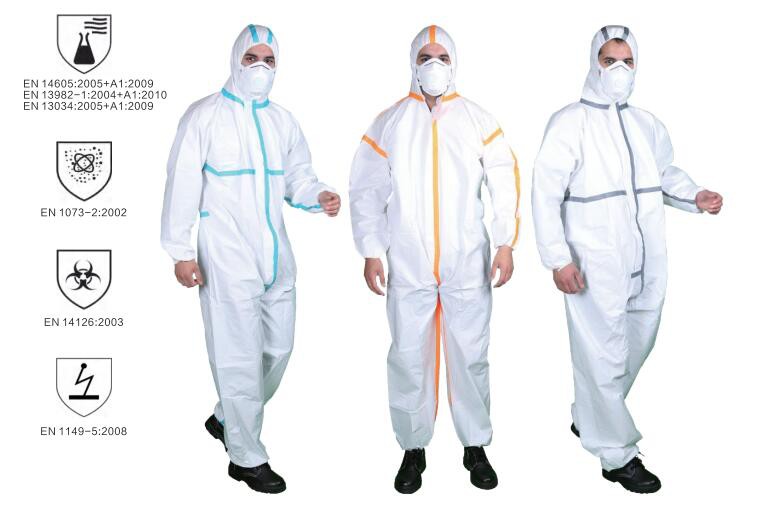

SMS Coveralls are comprised of a micro porous film and polypropylene to create a nonwoven liquid proof material. Heavy-Duty Coveralls offer better solvent resistance, superior splash protection and protection against nonhazardous particulates.

What are coveralls used for?

Coveralls must be of a suitable design and material to protect people from a given hazard. For example, coveralls to protect from sparks and hot particles should be made of a flame-resistant (FR) fabric and should not have wrist or leg turn-ups that could catch sparks. In addition to FR fabrics, manufacturers specialise in developing a range of textiles with relevant properties to protect from various hazards, such as anti-microbial textiles for use in healthcare and food preparation, or a combination of flame retardant fabric with high visual properties for people working with sparks who also need to be seen – for people working on a rail infrastructure, for example.

Safety suppliers offer a wide range of general and special purpose protective clothing to handle various hazardous tasks, including disposable coveralls for processes such as asbestos removal.

All protective clothing is of course a compromise between comfort and protection: in warmer environments the best comfort would be derived from wearing a vest, shorts and sandals or even less. This attire, however, wouldn’t help much if your working environment poses the risk of being splashed with hydrochloric acid. On the other hand, the best protection might be derived from sealing yourself inside a lead-lined steel box, but it wouldn’t be too comfortable – or practical.

Suggestions when using the coveralls

When coveralls become soiled or contaminated. When working with particular significant hazards, e.g., asbestos or lead, it is recommended that coveralls are commercially laundered by specialist launderers, in order to prevent workers exposing family members to these hazards by bringing soiled coveralls home to wash.

It is also recommended that prepare a place where workers can keep their own clothing free of debris that may be present in the atmosphere, or which could be transferred from the soiled coveralls. An example is to provide each worker with two lockers – one to keep clean clothes in, and one to keep work coveralls in.

In summary

While many people work in occupations that do not require any type of coveralls, there are a large number of people who rely on protective coverall items on a daily basis. These items are designed to do more than just protect the clothing underneath. They also provide warmth, keep contaminants away from the skin, ward off cuts and scrapes, and keep contamination away from products that could harm others (for example, in food preparation). The right type of coverall is important for workers on the job, and safety managers should ensure that employees are properly protected.