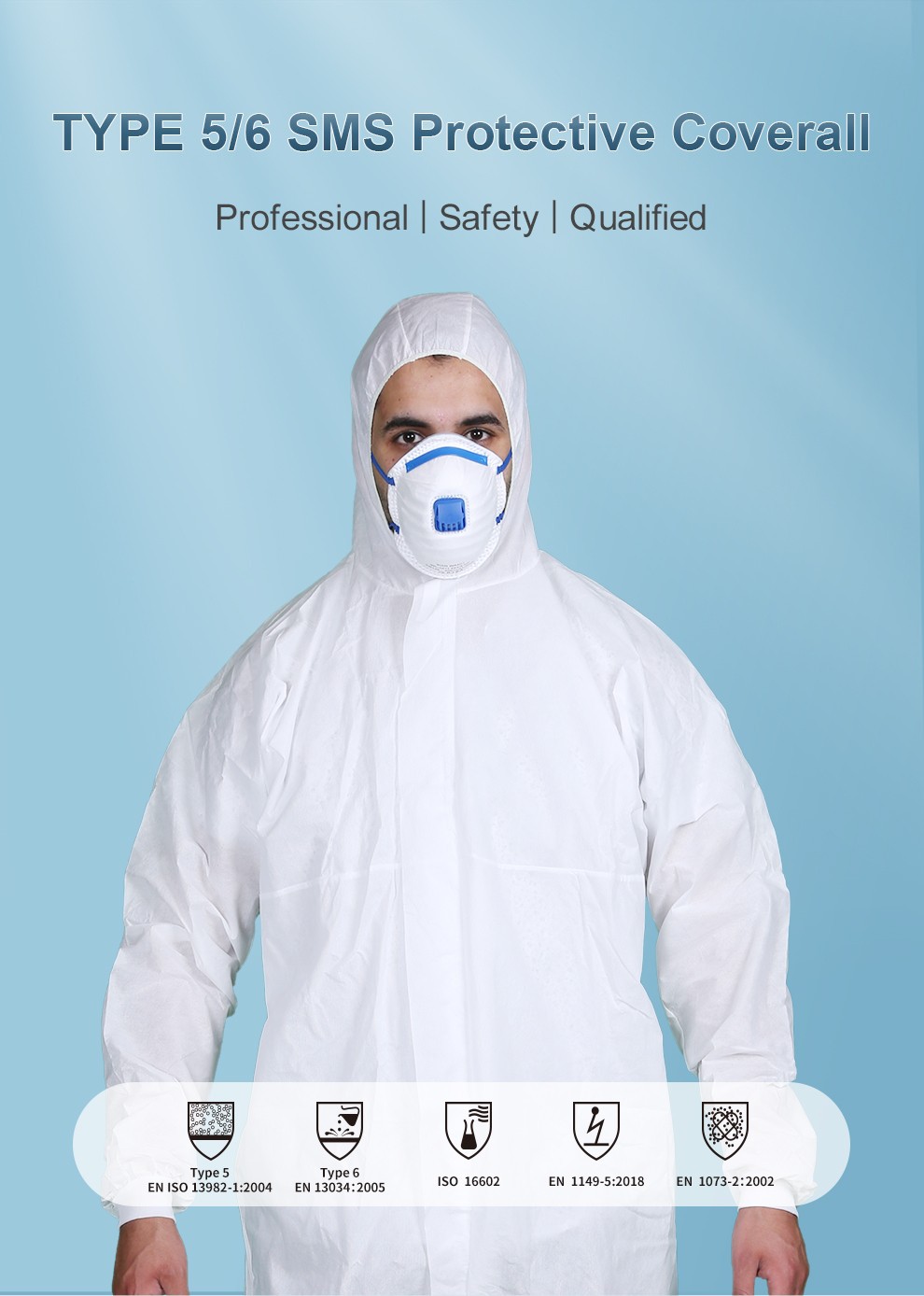

Type 5 6 Coverall

Article No.: WLO3003

This type 5 6 coverall is made of 3-layer SMS material with high breathability and dust barrier, whilst maintain high moisture vapour transmission rate which allows vapour escape trough fabric and keep cloth inside cool and comfortable.

Product Description

This type 5 6 coverall is made of 3-layer SMS material with high breathability and dust barrier, whilst maintain high moisture vapour transmission rate which allows vapour escape trough fabric and keep cloth inside cool and comfortable.

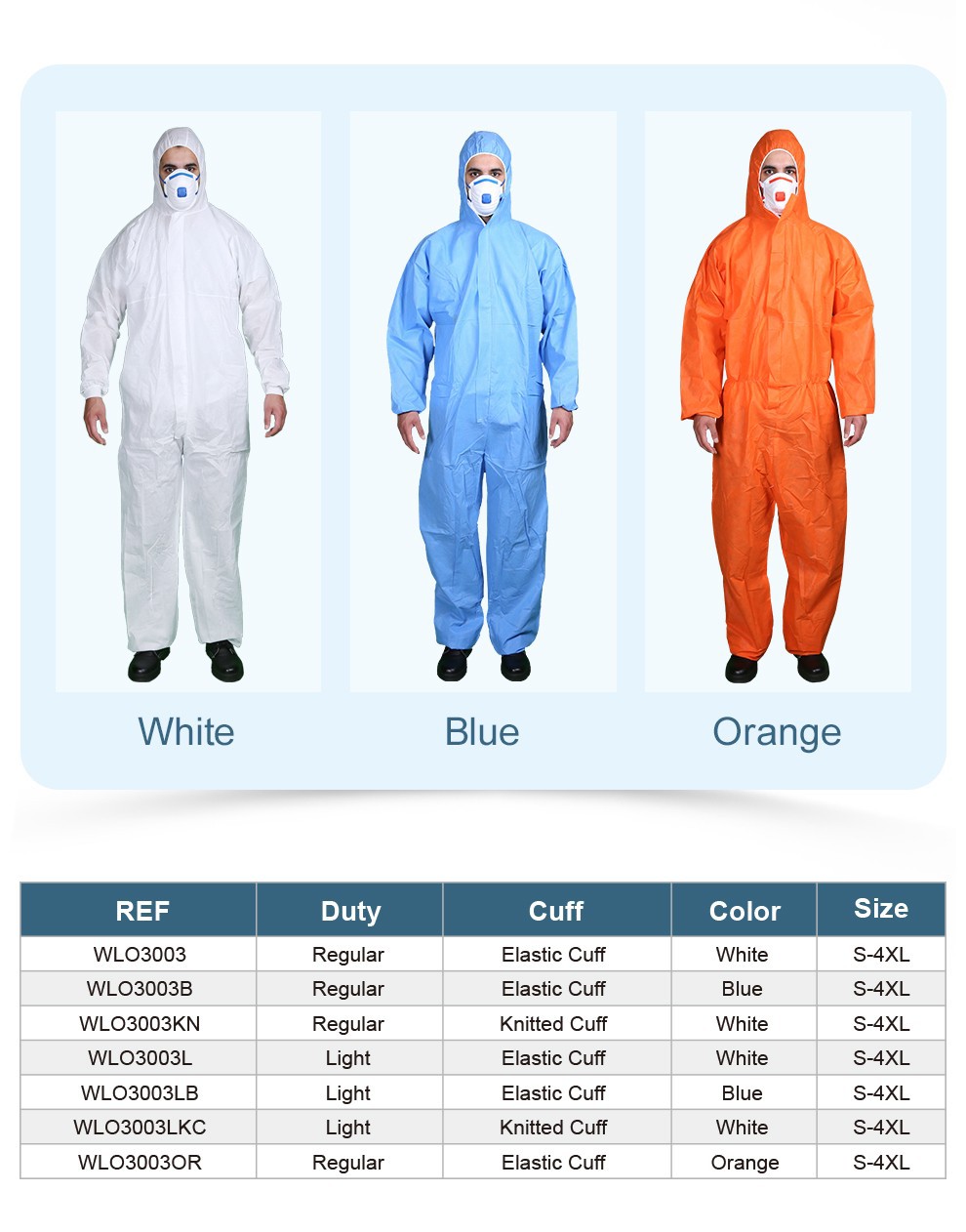

Product Specifications

| Brand | HEALEECARE |

| Model Number | WLO3003 |

| Material | SMS Non-woven Polypropylene |

| Size | S/M/L/2XL/3XL/4XL |

| Color | White/Blue/Orange |

| Certification | CE, ISO 9001, ISO 13485, FDA, Sedex |

| PPE Category | Category III |

| Protection Standards | EN ISO 13982-1, EN 13034, EN 1073-2, EN 1149-5 |

| Performance Levels | Type 5, Type 6 |

| Applications | Medical, Industrial, Chemical, Agricultural, Cleaning, and Disinfection, Painting |

| Shelf Life | 3-5 Years |

| Package | 1 PC/Polybag, 25/50 PCS/Carton, Vacuum packing available |

Product Applications

- Limited biological hazards and infective agents

- Painting and dust proof

- Industrial cleaning

- Emergency services

- Industrial pharmaceutical manufacturing

- Agriculture and veterinary service

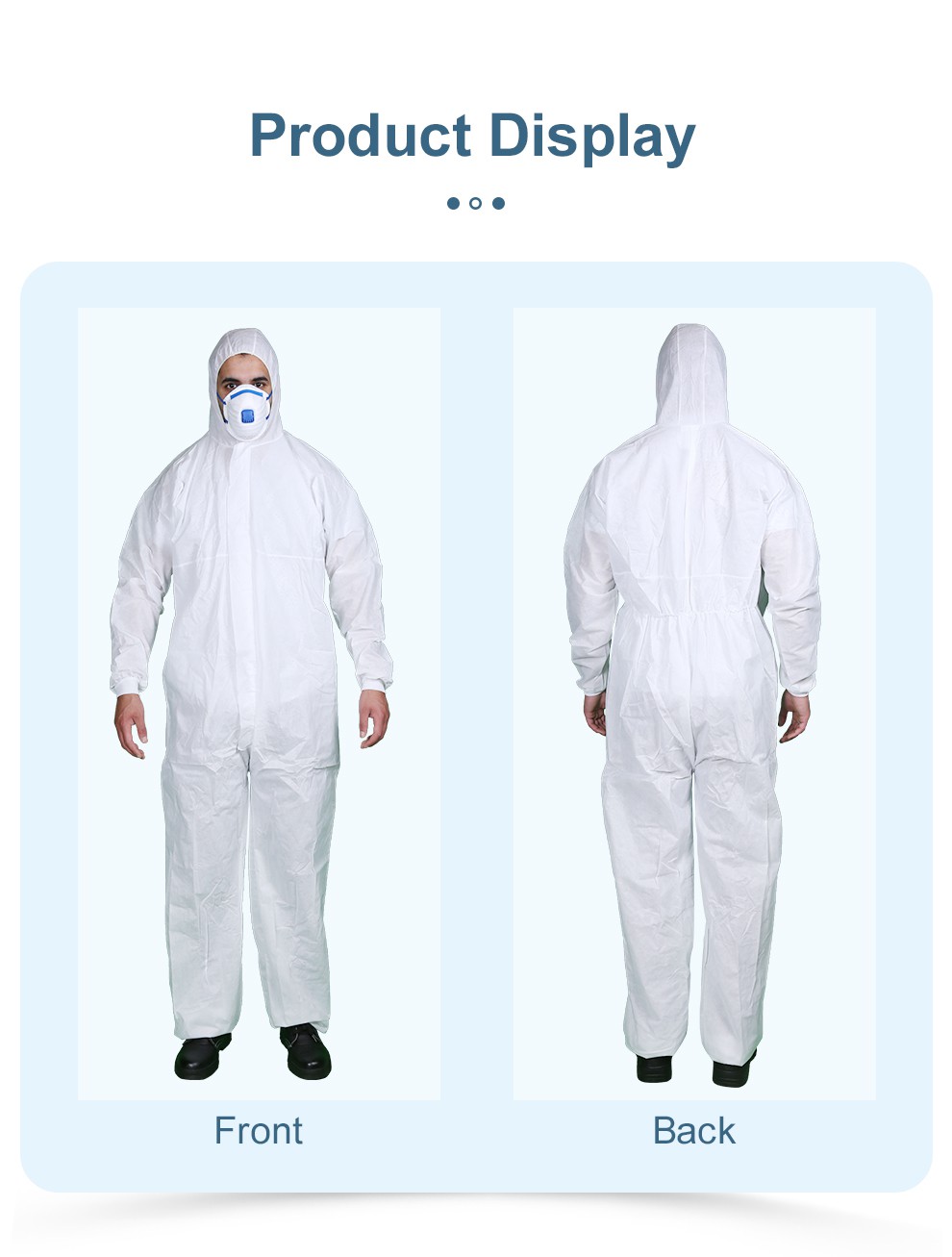

Product Pictures

Product Knowledge

What is a Type 5 6 coverall?

TYPE 5 and 6 SMS Protective Coverall protects against hazardous dusts (Type 5) and splash protection from light liquid spills (Type 6). The disposable coveralls are made of a breathable and lightweight material to promote safety and comfort.

What does SMS mean in fabric?

Spunbond + meltblown + spunbond (SMS) characteristics

SMS starts with two layers of the spunbond polypropylene described earlier. However, it takes things further by layering them with a central layer of meltblown nonwoven fabric.

What are the benefits of SMS material?

Online compounding is SMS non-woven fabric compounding that can be achieved through spunbonding and meltblown equipment on the same production line, the so-called one-step SMS non-woven fabric (on-line compounding). SMS non-woven fabrics are spread on a moving mesh curtain to form spunbonded, meltblown, and spunbonded composite fiber layers, and then thermally bonded through a hot rolling machine, and finally through a winding machine to form SMS non-woven non-woven fabrics cloth.

SMS non-woven fabrics make full use of the advantages of spunbond and meltblown technologies. The spunbond layer increases the strength and wear resistance of the product, and makes up for the weakness of the low strength of the meltblown fabric. The meltblown spinning fiber reaches 1~4μm, can improve the uniformity and barrier properties of the product, and can make up for the poor uniformity of spunbonded nonwovens.

Send Inquiry