The Differences Between PP Nonwoven Fabric And SMS Non-woven Fabric

Feb 20, 2023

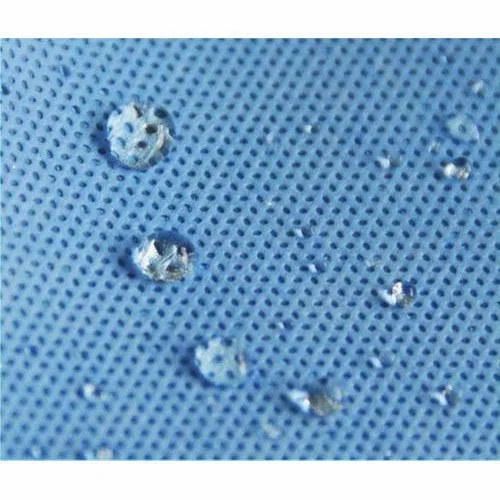

SMS non-woven fabric, the whole name known as: Spunbond + Meltblown + Spunbond Nonwovens. It's a combination of spunbond and melt-blow. Its properties: non-toxic and tasteless, efficient bacteria isolation. Through special treatment of equipment, it can achieve anti-static, anti-alcohol, anti-plasma, water repellent and water production.

This kind of fabric is often used in following situations:

1. Medical and health labor protection products such as surgical gowns, surgical caps, protective clothing, hand washing clothes, handbags, etc.

2. Sanitation products such as filter non-woven fabric, oil cloth, rag.

3. Heat insulation raw materials and clothing accessories.

4. Anti-feather non-woven fabric.

PP non-woven fabric is made by high temperature melting, spinneret, mesh, hot pressing and winding production. The material component is fiber. PP's full name is polypropylene, it is composed of directional or random fiber, it is a new generation of environmental protection materials. The main features are moisture-proof, breathable, flexible, light weight, flame retardant, easy to decompose, non-toxic and non-irritant, rich color, recyclable and other characteristics. It is called cloth because it has the appearance and certain properties of cloth.

At present, the raw material of most non-woven fabrics is polypropylene, while the raw material of plastic bags is polyethylene. Although the two substances have similar names, they are far apart in chemical structure. The chemical and molecular structure of polyethylene has quite strong stability and is very difficult to degrade. But polypropylene's chemical structure is unstable and its molecular chains can be broken, allowing it to degrade effectively and enter the environmental cycle in a non-toxic form.