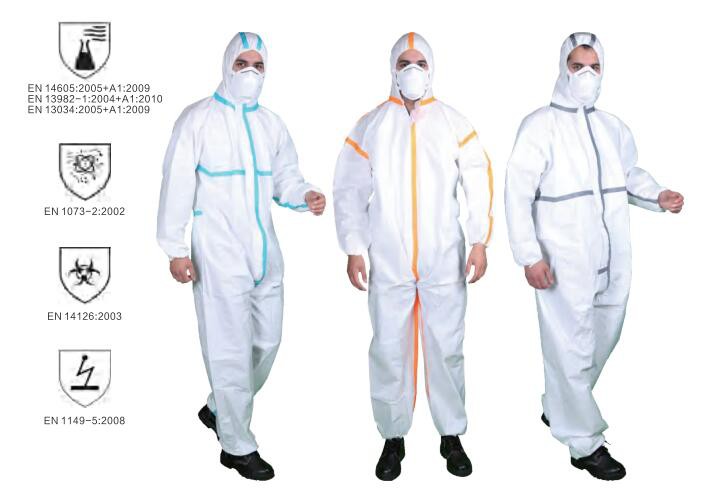

Protective Coveralls With Hood

Article No.: WLO3001

One-piece design coverall with hood, shoe covers, zipper at front opening covered by flap, elasticated cuffs, ankles, hood and waist, heat sealed seams with tape.

Article No.: WLO3001

One-piece design coverall with hood, shoe covers, zipper at front opening covered by flap, elasticated cuffs, ankles, hood and waist, heat sealed seams with tape.

Product Description:

Garments are composed of Non-woven microporous laminated film, providing an ideal balance of protection, durability and comfort.

Permeable to both air and water vapor, yet repels water-based liquids and aerosols.

Protection against infectious diseases.

Breathable, lightweight and flexible material for comfort.

Elastic closing design at the waist and ankle joints to ensure the conformability of protective clothing

Standard:

EN 14605: 2005+A1: 2009-Type 4: Protective clothing against liquid chemicals

EN ISO 13982-1: 2004+A1: 2010-Type 5: Protection against hazardous dry

particles

EN 13034: 2005+A1: 2009-Type 6: Protection against light spray of liquids

EN 14126: 2003+AC: 2004-Protection against biological hazards and infective

agents

EN 1073-2: 2002

EN 1149-5: 2018

-Protection against radioactive contamination

Protective Coveralls Application:

It can provide barrier and protection for medical staff to directly contact with patients or suspected patients.

Applications for it include maintenance and dismantling jobs in the nuclear industry, pharmaceutical manufacturing or in research and biosecurity laboratories, as well as in medical applications and when exposed to biological hazards

To provide protection when an outbreak occurs such as SARS, Ebola, COVID-19, etc.

What are the type of coverall standards ?

The goal of a disposable coverall is to safeguard individuals by chemical, physical and biological dangers. Healthcare staff are working during scenarios where unseen pathogens can easily come from any direction. The coverall typically provides 360 certifications of protection and provides a higher level of safety shield compared to medical gowns. The user of protective clothing have to be aware that no one protective garment can avoid most hazards. Protective clothing and various other protective methods should therefore end up being combined. The higher the degree of chemical type protective clothing, the greater the chance of contamination.

EN ISO 13688 defines the requirements for a coverall. It identifies general performance requirements for ergonomics, innocuousness, size designation, aging, suitability, and marking of protective clothes. The regulation divides coveralls in to 6 suits.

Type 1: Gas Tight Suits (EN 943 part 1)

Protects against liquid and gaseous chemicals. More or less equivalent to US level A.

Type 1a: Self-contained breathing apparatus wore on the inside.

Type 1b:Self-contained breathing apparatus worn on the outside.

Type 1c:Air supply via a compressed-air hose system.

Type 2: Non-gas Tight Suits (EN 943 part 1)

Protects against liquid and gaseous chemicals. More or less equivalent to US level B.

Type 3: Liquid Tight Suits. (EN 14605)

Protects against liquid chemicals for a limited period.

Type 4: Spray Tight Suits (EN 14605)

Protects against liquid chemicals for a limited period. More or less equivalent to US level C.

Type 5: Particulate suits (EN ISO 13982-1)

Protects against airborne dry particulates for a limited period.

Type 6: Reduced Spray Tight Suits (EN 13034)

Protects against a light spray of liquid chemicals. More or less equivalent to US level D.

Hot Tags: protective coveralls with hood, China protective coveralls with hood manufacturers, suppliers

Send Inquiry