How To Classify Non-woven Fabric? Why Is It Environmentally Friendly Material?

Sep 12, 2019

The fiber used in the production of non-woven fabrics is mainlyPolypropylene (PP), polyester (PET). In addition, there are nylon (PA) and viscose fibers., Acrylic, Ethylene (HDPE), Polyurethane (PVC). According to the application requirements, non-woven fabricsOne-time application And durable type.

According to the production process is divided into:

1.Spunlaced nonwovenThe spunlace process is to spray a high-pressure fine water stream onto one or more layers of the fiber web so that the fibers are entangled with each other, so that the fiber web can be reinforced and has a certain strength.

2. Heat-bonded non-woven fabric: Thermally-bonded non-woven fabric refers to a fibrous or powdery hot-melt adhesive reinforcing material added to the web, and the web is further fused and cooled to form a cloth.

3. Pulp airlaid non-woven fabric: airlaid non-woven fabric can also be called dust-free paper, dry papermaking non-woven fabric. It uses the air-laid technology to open the wood pulp fiber board into a single fiber state, and then uses a gas flow method to agglomerate the fibers on the mesh curtain, and the fiber web is further reinforced into a cloth.

4. Wet-laid non-woven fabric: The wet-laid non-woven fabric is obtained by opening a fiber raw material placed in an aqueous medium into a single fiber, and simultaneously mixing different fiber raw materials to form a fiber suspension slurry, and the suspended pulp is conveyed to a web forming mechanism, and the fiber is In a wet state, the net is then reinforced into a cloth.

5. Spunbond nonwoven fabric: Spunbond nonwoven fabric is a filament laid in a web after the polymer has been extruded and stretched to form continuous filaments. The web is then bonded, thermally bonded, and chemically bonded. Or mechanical reinforcement method to make the web into a non-woven fabric.

6. Meltblown non-woven fabric: melt-blown non-woven fabric process: polymer feeding---melt extrusion---fiber formation---fiber cooling---forming into the net---reinforcing into cloth.

7. Needle-punched non-woven fabric: Needle-punched non-woven fabric is a kind of dry-laid non-woven fabric. The needle-punched non-woven fabric is a puncture effect of a lancet, and the fluffy fiber web is reinforced into a cloth.

8. Non-woven fabric: Non-woven fabric is a kind of dry non-woven fabric. The stitching method uses warp-knitted coil structure, web, yarn layer and non-woven material (such as plastic sheet, plastic thin metal foil). Etc. or a combination thereof is reinforced to form a nonwoven fabric.

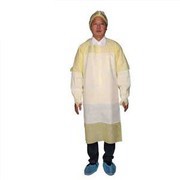

9. Hydrophilic non-woven fabric: mainly used in the production of medical and health materials to achieve a better feel and not to scratch the skin. For example, sanitary napkins and sanitary gaskets are hydrophilic functions using hydrophilic nonwoven fabrics.

The non-woven fabric has a soft, breathable and flat structure of new fiber products, which has the advantages of no lint formation, strong, durable, silky softness, and is also a kind of reinforcing material, and also has a cotton feeling, compared with cotton fabric. The non-woven bag is easy to form and is inexpensive to manufacture.

It is a new generation of environmentally friendly materials with water repellent, breathable, flexible, non-combustible, non-toxic, non-irritating and rich colors. If the material is naturally decomposed outside, it has a longest life of only 90 days. It is decomposed within 8 years in the room. It is non-toxic, odorless and has no residual substances when burned, so it does not pollute the environment, so environmental protection comes from this. .

In terms of environmental protection, the raw material of most of the non-woven fabrics currently used is polypropylene, and the raw material of the plastic bags is polyethylene. Although the two substances have similar names, they have a far different chemical structure.

The chemical molecular structure of polyethylene has considerable stability and is extremely difficult to degrade. Therefore, it takes 300 years for the plastic bag to be decomposed. The chemical structure of polypropylene is not strong, and the molecular chain can be easily broken, so that it can be effectively degraded. And in the non-toxic form into the next environmental cycle, a non-woven shopping bag can be completely decomposed within 90 days. Moreover, the non-woven shopping bag can be reused more than 10 times, and the environmental pollution degree after disposal is only 10% of the plastic bag.

The disadvantage of the non-woven fabric is that it is inferior in strength and durability, and cannot be washed like other fabrics. Since the fibers are arranged in a certain direction, they are easily split from a right angle direction and the like.