How to Choose an Appropriate Type 5 and Type 6 Protective Clothing

Sep 19, 2022

Available on the market you will find distinct forms of CE certified safety clothing of type 5 and type 6. Some of these people claim better protection and some have the best economic alternative. Users shall therefore make a great extra effort to find ideal protective clothing. How do I choose the right protective apparel?

Here are 2 facts you need to know before choosing the safety clothing of type 5 and type 6.

Safeguard Purpose:

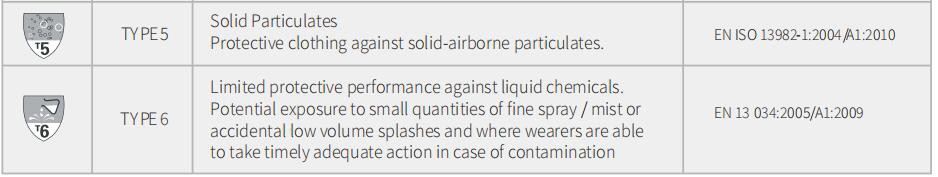

It 's the essential part00 . Which are the fact that certifications of type 5 and type 6 are applied related to different protection purposes? Below can be a brief summary of all these certifications.

Type 5 Certification: Dry Particle Suits

Performance requirements for compound protective clothing include full body prevention of airborne solid debris predicated on Regulation EN Iso 13982- 1: 2004+ A1: 2010.

Type 6 Certification: Reduced Spray Suits

Type 6 chemical protective garments are based on EN 13034: 2005+ A1: 2009.the performance requirements for chemical protective clothing involve limited protection against liquid chemicals.

For various protection purposes and protection of protective clothing, certificates in type 5 and 6 will be employed. A type 6 coverall is more suitable for dangerous liquid spray situations. If environmentally friendly risk relates to harmful particulate matter, Type five coverall should then be regarded .

Materials Structure

The material used regarding protective clothes are very different for order to acquire protection varied purposes. InType 5 and Type 6 certified protective garments, there are two common materials options in the market , one particular is Multi-layer SMS fabric, while the other can be PP nonwoven with a Laminated Film.

The Multi-layer SMS fabric is a decent choice for the protection from particulates. It has minimum 3 layers, and the middle part, which provides good particulate filter is referred to as melt- blown. The material also usually provides decent air permeability. For the phrasing SMS, it is a combination of materials structures, which is Spunbond( S), Melt- blown( M) and Spunbond( S). Some suppliers may well offer different combinations, namely SMMS or SMMSSMS. But with that said , the theory may be the melt- broken layer provides filtration features in hazardous particulates.