7 PPE Fabrics You Need To Know

Mar 09, 2023

From industril environments to medical workplace to agricultural and food making, determining the right type of fabric to wear to keep yourself safe during work is incredibly important. However, many professions require their workers to wear personal protective equipment (PPE), but it is important for them to choose what type of protective faric. The following 7 PPE fabrics are mainly used to make protective clothing, let's go ahead.

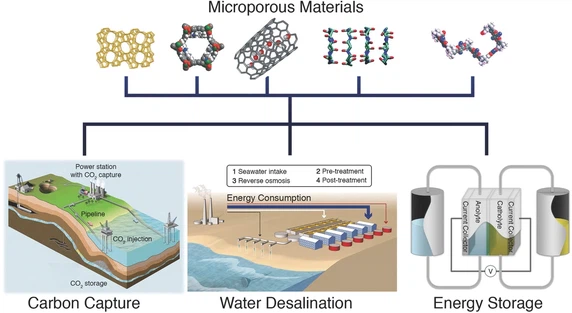

1. Microporous

Comprised of breathable and laminated microporous film, this non-woven fabric is known to provide a barrier against biological pathogens. Microporous materials (Fig. 8.3) can be defined as solids, containing interconnected pores of less than 2 nm in size. Thus, they possess large surface areas, typically 300–2000 m2/g as measured by gas adsorption [13]. Example include zeolites, AlPO4, metal organic frameworks (MOFs), clays, carbon, etc.

Microporous materials are often used in laboratory environments to facilitate contaminant-free exchange of gases. Mold spores, bacteria, and other airborne contaminants will become trapped, while gases are allowed to pass through the material. This allows for a sterile environment within the contained area. It can also be used in a variety of protective clothing articles, from gowns and full-body suits to coveralls, aprons, and even boot and shoe covers.

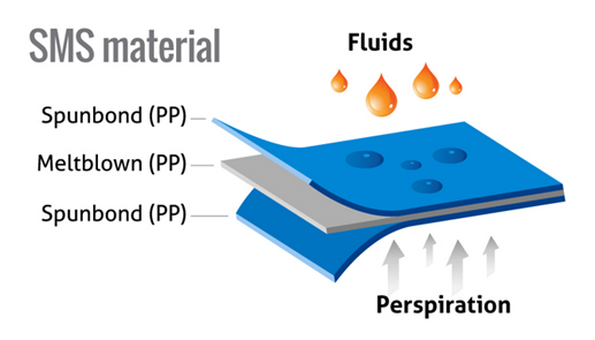

2. SMS (Spunbond Meltblown Spunbond)

Spunbond-Melblown-Spunbond (SMS) Spunbond-meltblown-spunbond (SMS) materials are multi-layered fabrics, commonly used in medical gowns, face masks, drapes, and sterilization wraps. They are made of 100% polypropylene.

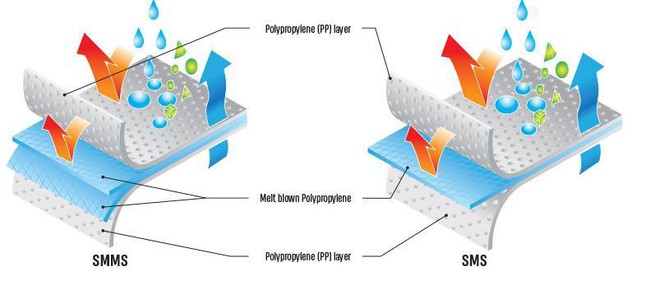

3. SMMS(Spunbond Meltblown Meltblown Spunbond)

SMS is the abbreviation of "Spunbond + Meltblown + Spunbond Nonwovens", that is a combined nonwoven fabric which two layer spunbond have been combined with one layer meltblown nonwovens inside, conforming them into a layered products, called SMS nonwoven fabric(spun-melt-spun), if combined with two layer meltblown nonwoven inside, it's called SMMS nonwoven fabric (spun-melt-melt-spun), in the same way, combined with three layer meltblown nonwoven inside, it's called SMMMS nonwoven fabric (spun-melt-melt-melt-spun).

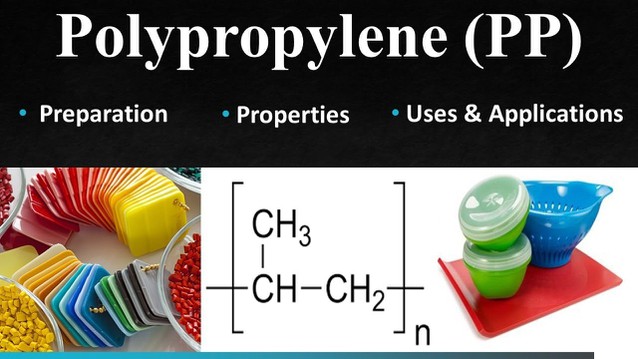

4. PP(Polypropylene)

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene.

Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance.

5. PE(Polyethylene)

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic.[5] It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bottles, etc.).

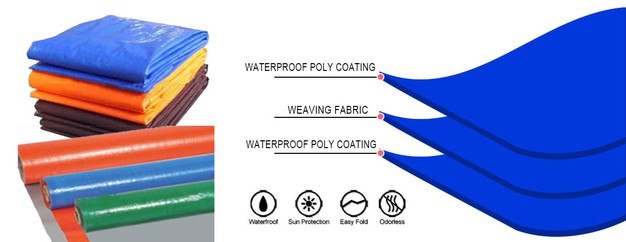

6. PE Coated(Polyethylene Coated)

PE coated paper is layered with polyethylene, providing a very strong moisture and grease barrier. Unlike wax coated paper, PE can be used for hot purposes as it won't melt and affect your product.

7. CPE(Chlorinated Polyethylene)

CPE is the standardized acronym for thermoplastic chlorinated polyethylene elastomer, which is produced by chlorination of polyethylene. The chlorine content can be 15 to 30% by weight.